100kW Motor Dynamometer

- rebecca-mc

- Jun 7, 2021

- 1 min read

In 2020 and 2021, I led the electrical, mechanical, and systems-level design and implementation of a 100 kW dynamometer (dyno) to enable testing and data collection of electric motors and inverters for the FSAE team.

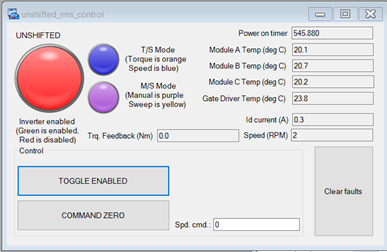

I designed, assembled, and tested a PCB for low voltage CAN communications as well as a high voltage distribution box containing sensors, interlocks, and bus bars. I developed and followed rigorous test plans and procedures to safely integrate the system and test all required functions. I also managed the software development of a GUI to run automated torque-speed sweeps. This project improved my skills in project management, integration and testing, and high voltage electronics.

Now that I have graduated, I continue to consult regularly with the FSAE team as they further expand on the dyno's capabilities.

My work for the dyno even got featured on the MIT MechE Twitter page!

Comments